How are fresh cocoa beans processed?

In order to be able to produce quality and pure cocoa powder, besides the strict production line, how to choose and process cocoa to keep the delicious and nutritious traditional flavor that the company has to offer. cocoa yield after processing. So how is the fresh cocoa fruit processed, let's find out the content below with Trong Duc cacao.

What month cocoa fruit is harvested

When the plant is about 2 and a half years old, it can give fruit, but usually from 3 to 4 years, the fruit after about 6 months from the date of fertilization will ripen and start harvesting.

Picking fruit: picking when the fruit is really ripe, it should not be too late because the seeds can germinate inside the fruit. And if picked too early, it can lead to low yield and poor product quality

Depending on the land where cocoa bears fruit in 1 or 2 seasons, in the Central Highlands, the tree usually produces only 1 fruit, but the product quality is considered to be the place with the highest product quality compared to other regions. cocoa planting. cacao has two flowering times and fruiting series, which is about April to May, will be harvested in October - November and flowers from October to November will be harvested in March - June. But depending on the care conditions of the householder, the annual weather in each region, cocoa flowers will come out sooner or later than 1 month.

When the cocoa fruit begins to ripen, the green color of the rind turns yellow and then orange. Note: do not let the flower pillow (where flowering) be damaged causing damage to the following season, and also create conditions for pathogens to enter the plant. Therefore, for the fruits at hand level, we use a knife to cut them, and for the taller ones, we use fruit picking tools to pick them.

Crushing the fruit to get the seeds: the work of crushing the fruit must be done immediately after picking the fruit, it should not be left for longer than 4 days because the cocoa will lose its taste, the time from beating the fruit to the time of fermentation is not more than 24 hour.

Currently, on the market, the retail price of fresh cocoa beans ranges from 120,000 to 150,000 / kg , but very few places sell them.

How to brew fermented cocoa beans

Step 1: Put the seeds in a wooden crate for incubation

There are many composting methods, but usually farmers do it using wooden crates. Before adding the seeds, then cover the top with banana leaves. We mix once every 48 hours. The incubation period is from 3 to 7 days (depending on the variety) Criollo only needs 3 days, while Forastero and Trinitario varieties need to incubate up to 7 days. To know if the beans are finished fermenting, use a knife to cut across the seeds to see if the tetrapods of the seeds turn from white or purple to chocolate brown, then the beans have finished fermentation.

To know if the beans have fermented enough, we can smell the barrel. When mixing, if you smell vinegar, the seeds are not fermented enough, in the last days when you smell the vinegar, it has changed to ammonia (slightly pungent smell), the seeds have fermented enough. At this point, if the seeds are cut, the dark purple color of Forastero and Trinitario has turned to a slightly darker purple, then the seeds have fermented well. Note that the purple color of Trinitario when not incubated is lighter than that of Forastero but also darker than the finished seed.

After brewing, put it in the water to scrub the rice, then let it dry

Note: fermentation plays a very important role in the quality of cocoa beans. The aroma of cocoa is only released during incubation, if improperly brewed, the fermentation has not reached the peak of fermentation, the quality of the beans will decrease a lot. During incubation, the temperature inside the bin can be up to 50oC, the outside is lower, so it's very important to mix well and remember to always keep it hot and humid. If the barrel is cold or less hot, the fermentation of the seeds will not be achieved and may rot.

Seed drying

Seeds after fermentation are scrubbed clean and then dried to reduce the moisture content from 60 to 6 - 7% for storage. Usually people dry them by spreading seeds in a thin layer on cushions, bamboo screens... for drying. Usually people make a drying rack about 40 - 50cm above the ground to prevent pigs, chickens and ducks from breaking. People dry like that about 8 - 15 days, then the seeds dry (depending on the sun more or less). After drying, it is necessary to choose the seeds of pests and diseases to separate and thus we have completed the preliminary processing.

Where to buy cocoa powder?

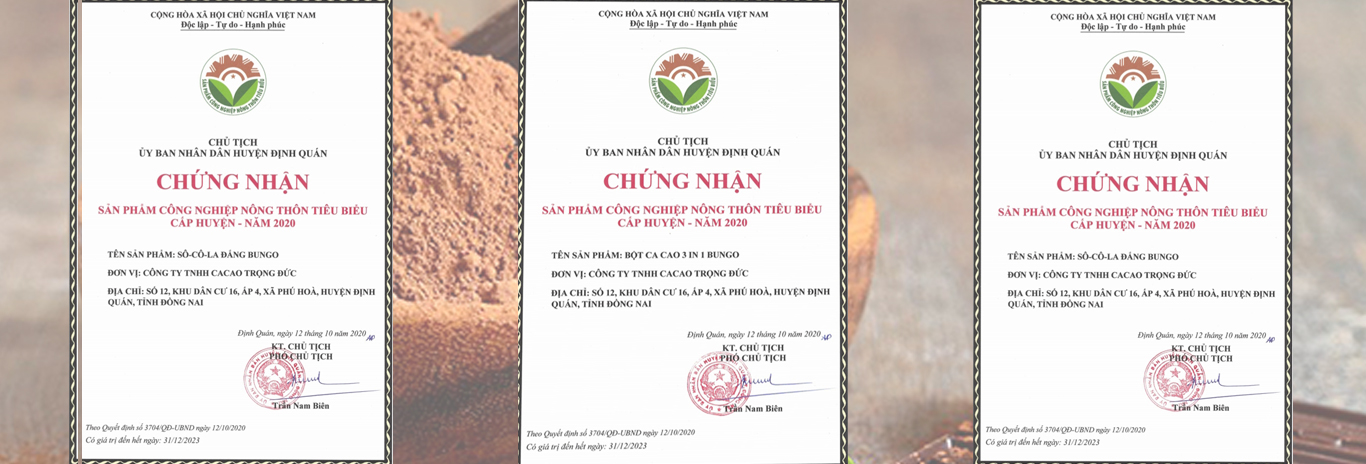

Cacao Trong Duc is proud to be a supplier of 100% pure cocoa powder products with a network of agents across the country. Trong Duc Cacao is committed to providing 100% pure products, without mixing impurities or additives.

For more information, please contact us via hotline or go directly to our unit's address for advice and the fastest quote!