Cách thu hoạch và chế biến ca cao đúng cách

Cocoa solemnity would like to introduce and guide how to harvest and process cocoa properly. Ensure the process so as not to lose the characteristic smell of cocoa

Steps for harvesting and processing cocoa

1. Harvesting ripe fruits:

When trees have a life span of 2 and a half years, they can start to give fruits, but usually the time is between 3 and 4 years, from the time of pollination to the time when the ripe fruit is in the period of 6 months start harvest.

Picking left fruits: Picking fruits that are really ripe, do not over-ripen the fruits because the seeds can germinate inside. And it is also not advisable to pick young fruits , so makes low productivity and low quality

- When the ripe starts, the green color of the left skin turns yellow and orange.

Note: When picking fruit, be careful not to damage or damage the flower (which is the flowering place) because it will damage the next crop, also facilitating invading pathogens enter the tree. The left-handed fruits use a cutting knife, and for a higher left , the fruit picking tools must be used to harvest.

- The process of beating fruit to get seeds: the left dam to get seeds must be done immediately after picking, should not be left for more than 4 days, the time from the left dam to remove the seeds until the fermentation is not more than 24 hours.

2. Process of fermenting fermented seeds

There are many different methods of incubation, but often farmers often use [cracker] or wooden crate. Before putting the seeds in, then use banana leaves to close them. [Nbsp] will be mixed once every 48 hours. The incubation time for 3 - 7 days (depending on variety) is like Criollo only need to be incubated for 3 days, while Forastero, Trinitario varieties are 7 days. To check if the fermented grain is complete, use a knife to cross the bead if the seed of the seed from white or purple turns to chocolate brown then the grain has finished fermenting.

To know if the cocoa beans are fermented enough, the can smell the bins. When the mixture smelled of vinegar, the fermenting grain was not enough, and if smelled the vinegar, it was transferred to the smell of ammonia (the smell of the declaration) was completed. Now, if you cut out the seeds, the dark purple color of Forastero and Trinitario has turned slightly dark purple, which is a good fermented grain. Note that the unburnt Trinitario purple has a lighter color than Forastero's, but is also darker than the finished grain.

When composting is finished, then bring it down to clean the rice shell, then bring it to the sun.

Note: The annealing has a very important role in the quality of cocoa beans. The fragrance of cocoa only comes out during incubation, if process is improperly brewed, has not reached the peak of fermentation, the quality of the grain will decrease to a lot of. Temperatures when incubated inside the bin can be up to 50 ° C, the lower part is lower, so mixing the bin is important and keeping the bin warm and humid is good. If the container is colder or less hot, the fermentation of the grain will fail and may rot.

- Drying seeds

After fermentation, clean the seeds and dry them to reduce moisture content from 60 to 6-7% for storage. Usually people dry by spreading a thin layer of seed on the mattress, bamboo ... to dry. Often people make a drying rig about 40 - 50cm from the ground to avoid swine, chicken and duck breaking. People dry like that for about 8 - 15 days, the seeds are dry (depending on how much or less sunshine). After drying, it is necessary to select all the seeds of pests and diseases so that we can finish the processing and selling stages.

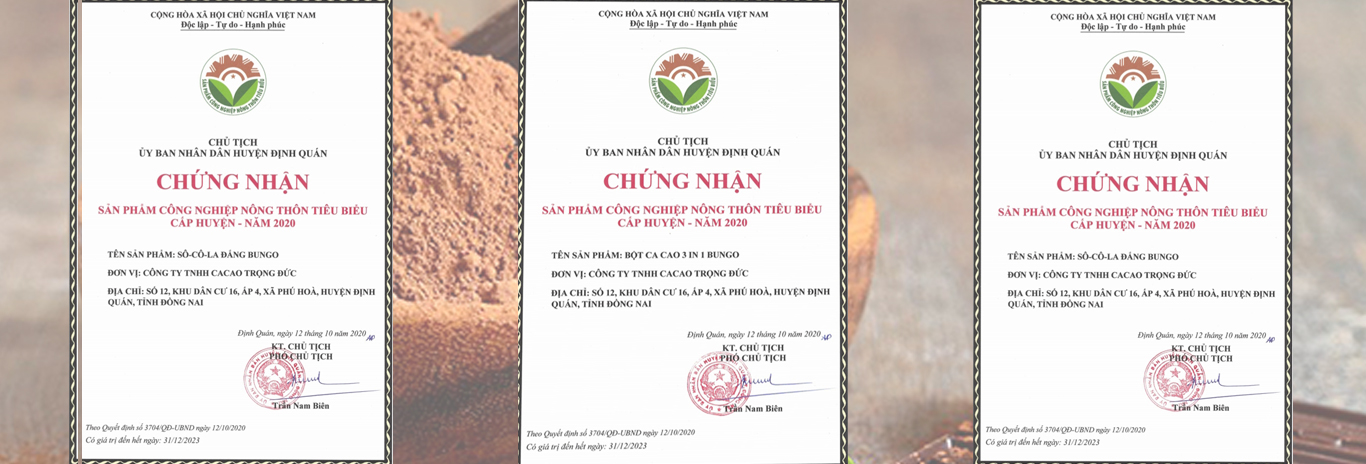

In German Cocoa specializes in providing cocoa seedlings, chocolate, pure cocoa powder ....... etc